The finished goods detection and counting system is a very easy, clear and efficient system for controlled production. It is perfectly suited for manufactories where each operator can see exactly how many products still need to be produced. It can easily be supplemented with a production trend indicator, displaying data from multiple lines or multiple line segments.

The sensor itself can be any PNP sensor, on narrower belts or reflective without reflector. The evaluation unit is concealed in a high IP56 rated box, the power supply for the whole assembly is solved by PoE, thus impacting the installation of additional cables, all with one LAN cable. Safe low voltage and lower maintenance requirements.

Thanks to PoE, the unit can be remotely switched off and power savings can be achieved, but the whole set, including LAN communication, consumes only 2.6 W.

The communication of the evaluation unit with the server is via http protocol with a very simple data structure, therefore this system can be easily integrated into Web and Cloud services, in-house, external or private cloud at home.

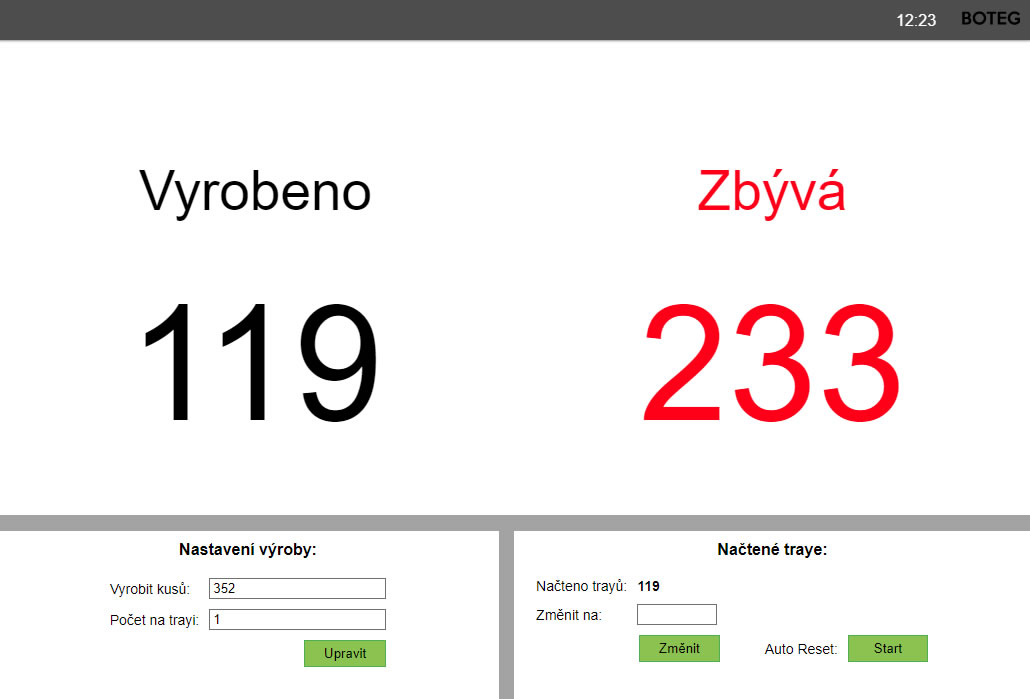

Visualization

Almost all of our systems are delivered as Web Applications, we believe this is the best way to easily visualise, save older hardware and it is also an option to use very cheap hardware such as Rapsberry, second hand POS tills and older no longer suitable workstations.

The visualization is fully and easily customizable, uses various animations and fully supports keyboard control. For example, in this solution, a simple wireless numeric keypad is sufficient to control the entire system and the Enter button can be used to enter and jump between fields.

The web application can run on an unlimited number of computers.